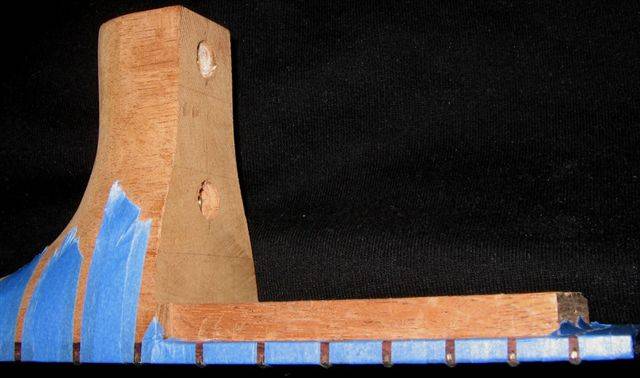

Michael – Yes the neck adjusts from the inside and the fb extension free floats. There will be a slight gap on each side of the neck where it enters the body – maybe .015 gap, but I think its impact could be minimized by installing a strip of black purfling on each side of the neck opening. I didn’t worry about it on this build since it’s a prototype.

Dave – I agree that the FP really lets the wood shine through. When I see it, I think “wood” instead of “plastic.”

Your description of how this neck joint works is correct. The three adjustable tee bolts butt against the wood of the neck heel. I did not install any brass rod inserts into the neck, but I can see how that might be a better way to go. Sharpened bolts into brass inserts would really hold the neck securely. I’ll let you know how this works.

Thanks for the encouragement and the pics. I thought about using the flying buttress braces, but on this parlor the upper bout was so small that I didn’t think that I would be giving up much by making it strong enough to take the pressure from the neck block. I think that the next time I’ll try the flying buttress idea, but I wonder if one running from the top would be enough. Martin uses bolt on necks and the bottom of the neck block is connected to the back by only the width of the kerfed lining.

Anyway, since I’ll never be a master builder, it sure is fun to experiment.

I’ll give you guys a full report when I finish this thing.

|

Very nicely done. You folks are eventually going to convince me to give it a try. I'd also like to hear more about the wood and neck attachment.

Very nicely done. You folks are eventually going to convince me to give it a try. I'd also like to hear more about the wood and neck attachment.

I like the Idea of two axis adjustment. So I gather that the heal is the tendon. How mush play in the mortise do you leave for the off center adjustment?

I like the Idea of two axis adjustment. So I gather that the heal is the tendon. How mush play in the mortise do you leave for the off center adjustment?